Diagnostic centers play a pivotal role in modern healthcare, serving as crucial hubs for early detection, accurate diagnosis, and effective treatment planning. This article explores the evolving role of diagnostic centers, highlighting the advancements that have reshaped the industry and the challenges they face in delivering quality care.

Advancements in Diagnostic Technology

- Advanced Imaging Modalities: Diagnostic centers now harness cutting-edge imaging technologies such as MRI, CT scans, and PET scans, enabling earlier and more precise disease detection.

- Genomic Testing: Genetic testing has become integral in diagnosing and predicting diseases, leading to personalized treatment plans and improved outcomes.

- Telemedicine Integration: Telemedicine platforms allow diagnostic centers to offer remote consultations, expanding access to specialized care and consultations.

- Point-of-Care Testing: Portable diagnostic devices provide rapid test results, enhancing patient convenience and facilitating immediate decision-making.

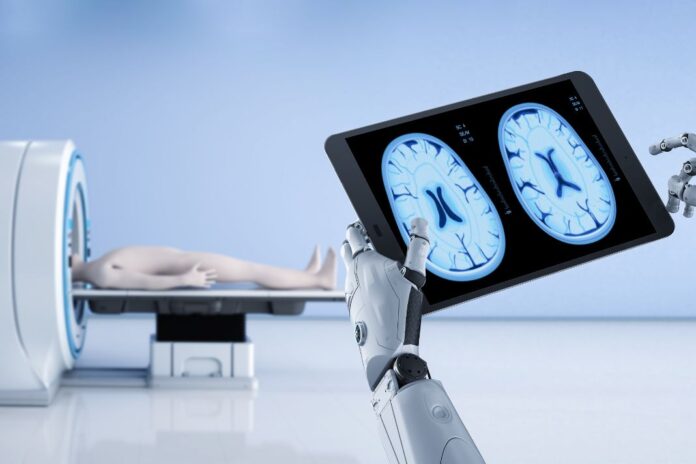

- AI and Machine Learning: Artificial intelligence and machine learning algorithms assist in data analysis, aiding radiologists and pathologists in interpreting complex data sets.

Challenges in Modern Diagnostic Centers

- Rising Demand: Increasing healthcare demands place a strain on diagnostic services, leading to longer wait times and potential delays in treatment.

- Data Security: Protecting patient data is paramount, as diagnostic centers are prime targets for cyberattacks. Robust cybersecurity measures are essential.

- Cost Pressures: Balancing the cost of advanced equipment and skilled personnel with affordable patient services is a constant challenge.

- Regulatory Compliance: Diagnostic centers must adhere to evolving healthcare regulations, which can be complex and time-consuming.

- Workforce Shortages: A shortage of skilled radiologists and lab technicians can hinder diagnostic centers’ ability to meet patient needs.

The Future of Diagnostic Centers

- AI-Driven Diagnostics: Artificial intelligence will continue to play a significant role in automating routine tasks and improving diagnostic accuracy.

- Patient-Centric Care: Diagnostic centers will prioritize patient experience and convenience, offering seamless scheduling and telehealth options.

- Remote Monitoring: Remote patient monitoring devices will integrate with diagnostic centers, allowing continuous tracking of patient health.

- Precision Medicine: Advances in genomics will drive personalized treatment plans, enhancing the accuracy of diagnoses and therapeutic choices.

- Population Health Management: Diagnostic centers will increasingly focus on population health initiatives to prevent diseases and reduce healthcare costs.

In conclusion, diagnostic centers are at the forefront of modern healthcare, leveraging advancements in technology to provide early and accurate diagnoses. However, they also face challenges related to demand, cybersecurity, and cost pressures. Embracing technological innovations, prioritizing patient-centric care, and adapting to evolving healthcare landscapes will be key to their continued success in delivering quality healthcare services.