Introduction: The world of diagnostic radiology in India is witnessing a transformative era, marked by advanced technologies that enhance both the precision of diagnosis and the safety of patients and healthcare professionals. As diagnostic centers across the country strive to deliver top-notch healthcare services, they are increasingly turning to cutting-edge radiation protection technologies. In this article, we will explore the future of radiation protection, highlighting emerging technologies that promise to revolutionize safety in Indian diagnostic centers.

The Evolution of Radiation Protection: Radiation has been an invaluable tool in medical diagnostics, but the need to protect against its potential hazards has driven continuous innovation in radiation protection. While traditional lead shielding remains effective, new technologies are set to redefine safety standards.

1. Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are poised to revolutionize radiation safety training. By providing immersive, interactive experiences, these technologies can help healthcare professionals better understand radiation risks and safety measures, improving compliance and reducing exposure incidents.

2. Real-time Dosimetry: Advances in real-time dosimetry devices are enabling healthcare workers to monitor their radiation exposure levels continuously. These wearable sensors provide immediate feedback, allowing professionals to adjust their practices in real-time to minimize radiation exposure.

3. AI-Powered Dose Monitoring: Artificial intelligence (AI) is making waves in dose monitoring. AI algorithms can analyze data from radiological procedures, detect irregularities, and suggest optimizations to reduce radiation exposure while maintaining image quality.

4. Nanotechnology: Nanotechnology is driving innovation in radiation protection materials. Nanomaterials can enhance the effectiveness of shielding while reducing the weight and bulkiness of protective gear, making it more comfortable for healthcare workers.

5. Robotics and Remote Control: Robotic systems are being developed to perform radiological procedures remotely, reducing the need for healthcare professionals to be in close proximity to radiation sources. This not only enhances safety but also allows for more precise procedures.

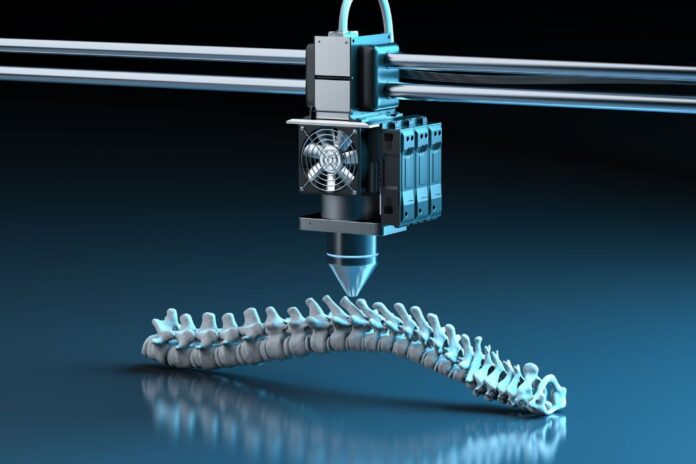

6. 3D Printing: 3D printing technology is being used to create customized radiation protection gear tailored to individual healthcare professionals. These precisely fitted aprons and collars offer superior comfort and protection.

7. Smart Infrastructure: Radiation protection is not limited to personal gear. Smart infrastructure solutions are being developed to monitor and control radiation levels within diagnostic centers. These systems can automatically adjust shielding and room configurations as needed.

8. Blockchain for Regulatory Compliance: Blockchain technology is being explored to streamline regulatory compliance in radiation protection. Secure, immutable records can help diagnostic centers demonstrate adherence to safety standards.

Conclusion: The future of radiation protection in Indian diagnostic centers is bright, thanks to emerging technologies that promise to enhance safety, precision, and efficiency. These innovations will not only reduce radiation exposure risks for patients and healthcare professionals but also contribute to the overall quality of healthcare services in India.

As diagnostic centers embrace these emerging technologies, they position themselves at the forefront of modern medicine, ensuring that the healthcare landscape in India continues to evolve, prioritize safety, and deliver world-class diagnostic services. The future is indeed promising for radiation protection in Indian diagnostic centers.